Quality

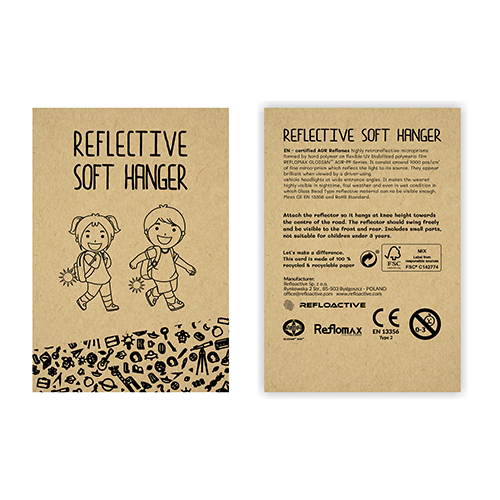

Our products are optionally confectioned and neatly packed in customized eco-packages, gift-sets along with customized individual labels and user’s manual. We use only biodegradable packaging, leading with state-of-the-art solutions, such as biofilm “plastic” foil made entirely with corn polymers.

The reflectors we offer do not contain phthalates or any harmful and toxic chemicals. During the manufacturing process we make sure that the environmental impact stays optimally reduced.

Reflomax

Refloactive is their only representative. Reflomax is a certified and widely recognized manufacturer of reflective films used mostly for car registration plates, but also in:

- Personal safety measures

- Road signs

- Vehicles marking

- Fashion and accessories

AGR MAXX

AGR MAXX is a very popular brand of reflective film thet conforms with several quality standards. As raw material, it meets the requirements of standard

EN 17353 with colors silver and yellow.

Each reflector made of AGR MAXX foil, with an unprinted surface of at least

15 cm2, meets the requirements of EN 17353 as a finished product, which we as a manufacturer can confirm with the Declaration of Conformity.

RGR

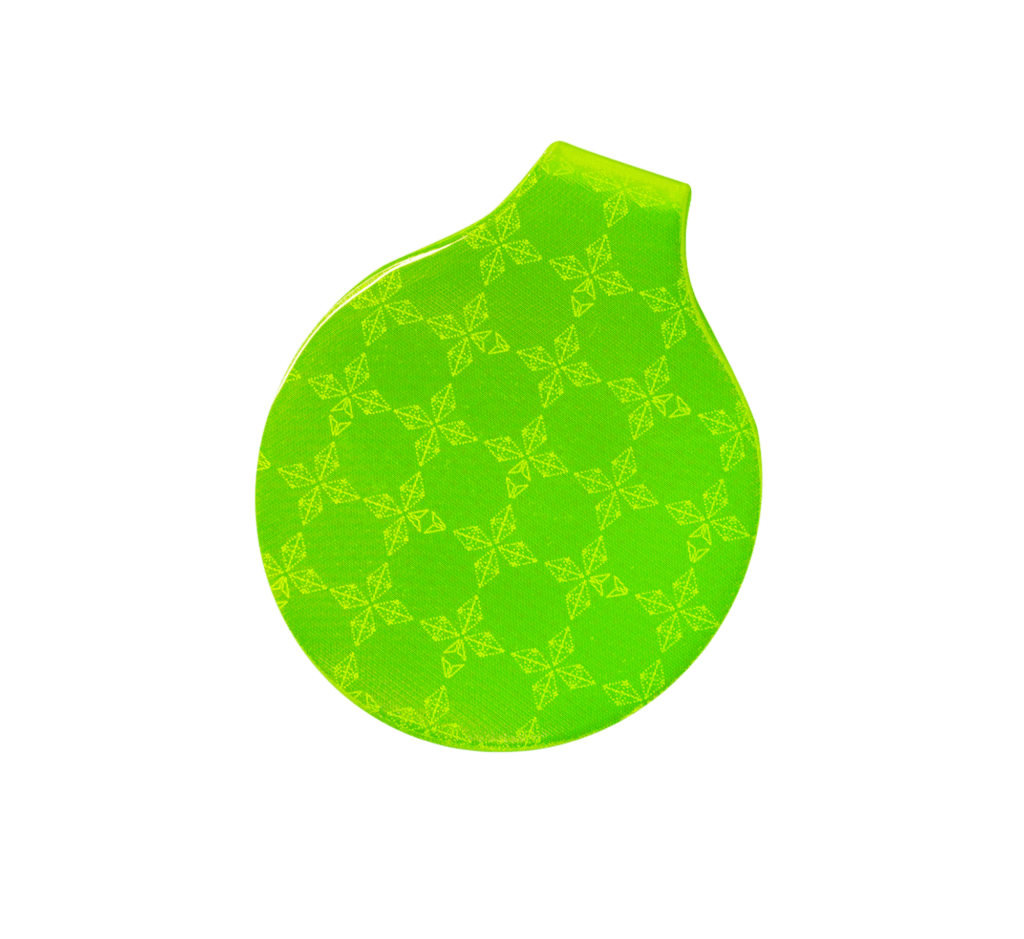

RGR offers a palette of colors to choose from: silver, yellow, green, blue, red, orange, pink Film tested free from heavy metals and plasticizers. Ideal for making pretty gadgets with print that are not necessarily safety products.

The foil does not comply with the reflective standard EN 13356 – also silver and yellow. This means that the concentration of the reflective prisms on 1 cm2 is not sufficient to meet the certification standards.

Note: The yellow and silver RGR film is indistinguishable from the certified AGR film on the eye – it looks the same and has the same holograms. However, the quality of the two slides is completely different and the reflective parameters of RGR gadgets are much lower than that of AGR. Therefore, the offer of some producers of reflective REFLOMAX films does not mean that certified films are used for the production, on the contrary, the price of the product shows that they offer a cheaper, non-certified replacement.

Film Logo Pattern

Each reflector made of standard AGR foil, with an unprinted surface of at least 15 cm2, meets the requirements of EN13356 as a finished product, which we as a manufacturer can confirm with the Declaration of Conformity.

Orafol

ORAFOL Europe is one of the leading manufacturers of innovative, self-adhesive graphic products, retroreflective materials, adhesive tape systems and high-quality polymer films. As a reliable source for industrial and commercial partners, ORAFOL is setting the highest standards in quality, innovation, service and environmental responsibility.

Oralite

ORALITE® is a registered trademark of ORAFOL Europe GmbH – a tough weather resistant, highly reflective sheeting designed to be high frequency welded to a vinyl backing into various shapes. It is composed of cube corner (microprism) retroreflective elements integrally bonded to a flexible, smooth-surfaced tough and weather resistant UV stabilized polymeric film. Orafol meets the latest requirements of standard EN 17353, which are more stringent than those of standard EN 13356, and the range of tests and their tests are significantly expanded.

The Print

We wish to preserve the protective qualities of the reflective films – therefore we recommend printing under the foil so that 100% of the reflective surface is retained. A reflector marked this way constitutes a certified personal protective equipment which creates a positive image of the advertiser. Other types of marking: screen printing on foil, digital printing on foil (also with transitions and raster)

Full color printing under the foil

This technique involves printing with solvent white backing foil (even full color with tonal transitions), then we add transparent reflective foil and weld the finished reflector together. The print is slightly less visible and oblique – but the marking is inconspicuous, soft and not limited in area.

RGR

This technique covers the foil and therefore reduces the reflective surface and protective properties, which might affect the product’s CE conformity report. In case of a limited surface, we usually recommend printing under the foil.

Film Logo Pattern

This technique covers the foil and therefore reduces the reflective surface and protective properties, which might affect the product’s CE conformity report. In case of a limited surface, we usually recommend printing under the foil.

We are ECO

ECO films

Our reflective films are free of toxic chemicals and tested negative for heavy metals. Folprint film is REACH-certified – it informs that the material is produced in the EU and no hazardous substances are found in the composition.

ECO packages

Our wrappings are biodegradable. Paper for the manuals is FCS certified and produced in Scandinavia. Film for single packaging is certified, made in Poland, safe in contact with food.

ECO polybags

We use polybags out of biodegradable plastic substitute.

Highest quality

Foam fillers

Our foam fillers are REACH-certified and of European origin.

Flocks

The raw material is produced in the EU and no heavy metals of hazardous substances are found in the composition.

Textile glue

Self-adhesive paper for the production of stickers is of production and FSC certified. Our glue does not contain any toxic substances.